Civil Engineering Products

Shibata undertakes to protect livelihoods and national lands from earthquakes, volcanic activities, flooding caused by climate anomalies, and other natural disasters. Our original products employing hybrid materials help address a host of vital needs. These include a rubber steel and an innovative bridge restrainer system developed to reduce earthquake disasters, structure protection materials for soil and water conservation projects, and waterproofing equipment against flood disasters. Here, we would like to introduce you Rubber Steel, one of our original disaster prevention products used for concrete structures at rivers, streams, canals, waterways, dams, seasides and coasts.

Rubber Steel, Sabo-related Product

Protective layers for concrete structures including debris barriers.

Alternatively these could be used at rivers, streams, canals, waterways, dams, seasides and coasts.

Alternatively these could be used at rivers, streams, canals, waterways, dams, seasides and coasts.

Background of Product Development

Japanese rivers have a steep gradient and are thus susceptible to sediment disaster following heavy rains, which often take a toll on people’s lives and assets. One such sediment disaster is debris flow that flushes boulders down the river. It was to prevent such disasters that debris barriers were constructed throughout Japan as a part of erosion control projects.

Concern arose, however, over the reduced performance of barriers caused by concrete structures having worn out after being subjected to repeated erosion from sediment flow.

Shibata’s answer to the problem was the development of Rubber Steel, a composite material made by integrating rubber and steel plates to attach to concrete surfaces. Focusing our activities on the impact of debris flow, the cause of concrete structures wearing out, we developed the protective layer.

Concern arose, however, over the reduced performance of barriers caused by concrete structures having worn out after being subjected to repeated erosion from sediment flow.

Shibata’s answer to the problem was the development of Rubber Steel, a composite material made by integrating rubber and steel plates to attach to concrete surfaces. Focusing our activities on the impact of debris flow, the cause of concrete structures wearing out, we developed the protective layer.

Superior in abrasion resistance

Dispersal and mitigation of impact energy

Corrosion-resistant structure

Debris flow

Worn-out debris barrier

Product Features

・Rubber attached to the concrete surface of a debris barrier

prevents wear and damage to the bank crown area with its

excellent abrasion and impact resistance in comparison to

concrete.

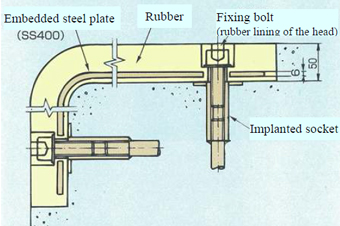

・Steel plates completely covered and integrated with rubber.

・Steel plates completely embedded in rubber cohesively by cure

adhesion, achieving a corrosion-resistant structure that shuts out

air, water, and other corrosive elements.

・Rubber Steel is fixed by implanting anchorages into concrete and

screwing tight fixing-bolts.

・The heads of the fixing bolts are also covered with rubber.

・Rubber Steel extends the service life of the structure and

reduces the frequency of repair and maintenance, and thereby

cuts running cost.

prevents wear and damage to the bank crown area with its

excellent abrasion and impact resistance in comparison to

concrete.

・Steel plates completely covered and integrated with rubber.

・Steel plates completely embedded in rubber cohesively by cure

adhesion, achieving a corrosion-resistant structure that shuts out

air, water, and other corrosive elements.

・Rubber Steel is fixed by implanting anchorages into concrete and

screwing tight fixing-bolts.

・The heads of the fixing bolts are also covered with rubber.

・Rubber Steel extends the service life of the structure and

reduces the frequency of repair and maintenance, and thereby

cuts running cost.

Illustrated cross-section of Rubber Steel

Practical Achievements

Yuhama debris barrier, Miyagi Prefecture

Himekawa debris barrier, Nagano Prefecture (gray type)